JonathanWagenet

2-Wheeled Autonomous Robot

Group: William Tredennick, Jonathan Wagenet

Purpose

- Implement positioning, sensors, obstacle avoidance, path planning from theory to complete a challenge course with an autonomous robot.

Challenges

- Develop robotic system from the ground up with little programming knowledge as mechanical engineers.

- Communicate motion and sensor data from low level system to high level computational system.

- Traverse challenge course by combining modules for autonomy.

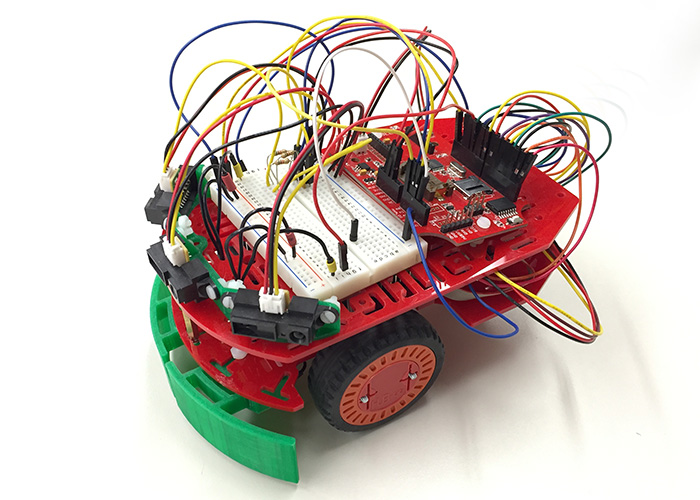

The robot. Mechanical front bumper switches.

Three proximity sensors. Seeeduino on top, Raspberry Pi below.

Test Drive

- Used MatLab to test algorithms before implementing on robot.

- Implemented positioning, obstacle avoidance, and feature extraction in simulation.

- Partial success implementing Enhanced Kalman Filter and path planning.

Design Details

- AVR microcontroller directly controls motors and collects data from sensors

- Raspberry Pi receives data, and handles positioning and decision making

- Implemented communication protocol to send sensor data and receive motor instructions

- »Kinematic model to estimate position from wheel encoders

- Bug-style basic obstacle avoidance

- Attempted implementation of Kalman filter for localization

- Low level I/O control written in C. High level control written in Python.

| Seeeduino | Raspberry Pi | |||

|---|---|---|---|---|

| Movement Output | Measurement | Decision Output | Computation | |

| Motor Voltage | Bump Sensors | Wheel Speed | Position Update | |

| Motor PWM | IR Sensors | Data Transfer | Wheel Direction | Target Orientation |

| Ultrasonic Sensor | ⇌ | Timing Delay | Target Distance | |

| Wheel Encoders | Obstacle Avoidance | |||

| Color Input | ||||

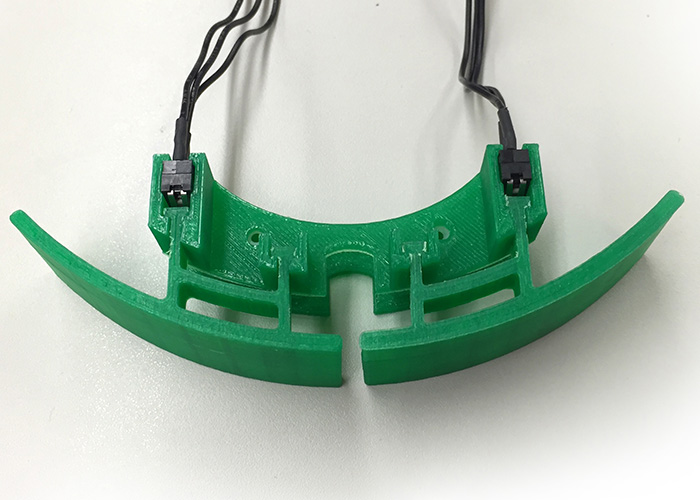

Mechanical Bumper

- Designed and 3D printed a mechanical bumper to reliably trigger left and right microswitches.

- Snug sleeve to mount switches without fasteners or glue.

- Two bumper guides for each bumper. Center guide travels when triggered head on and locks as a fulcrum when pressed at extreme angles.

- Bumper can reliably trigger the bump switch up to an angle of 45 degrees.

3D printed robot bumper with good angle coverage and reliable triggering.

Contributions

- I took charge writing most of the control code for the bot, as I have a better understanding of C and Python.In particular, I contributed the high level decision making and communication on the Raspberry Pi. Pythonwas selected because it is easy to write and debug. I also designed the bumper and mounts for the proximity sensors and electronics to keep the robot organized.

Limitations

- On a time crunch, we were unable to implement Kalman filter localization on the robot, which would help improve position estimation. We also avoided more complex algorithms like SLAM and more intensive mapping due to our limited programming experience.

Outcomes

- Learned how to read docs and set up port registers, ADC, hardware interrupts, and PWM.

- Worked with partner to develop and write control software for robot.

- Mixed success completing challenge course: unable to implement localization on robot and position from wheel encoders proved too inaccurate.